Margarine Plant Automation

Full automation

for margarine plant production process

We have 10 years+ experience

with automation solutions

1. We started journey in 2012

with first automation solutions for oil, milk, meat processing industry in Slovakia.

2. We were first Industry4.0 providers

in region focused on food processing plants and systems with organic material and high hygiene expectations.

3. In 2014 we automated first margarine plant

starting with weighting stage and developing into all facilities.

4. Until present we implemented several factories across EU region

Oil intake and Oil warehouses

(hot oils, cold oils)

Water Stage

(Boiler, Process water Preparation)

Oil Buffers

(Mixed oils stage)

KEVA Preparation Stage

(+ microcomponents dosing process)

Batch Weighting

Mixing and Emulsion Stage

Crystallization Process

Filling and Packaging machines

Product warehouse management

Heating and Amonia facility

Heat, amonia and air facilities

AISI304 stainless steel enclosures

for cabinets, panels, controls wit certificates

IP67 certified for food processing industry

Motor control cabinets

Logic Control Cabinets and Distributed I/O Cabinets

(Siemens)

Pneumatic Control Cabinets

(FESTO based)

Weighting Control Cabinets

(Dini Argeo based)

Robot Packaging

(FANUC based)

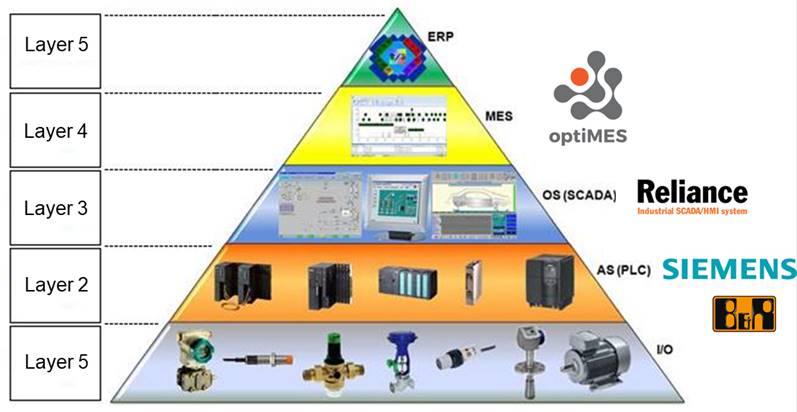

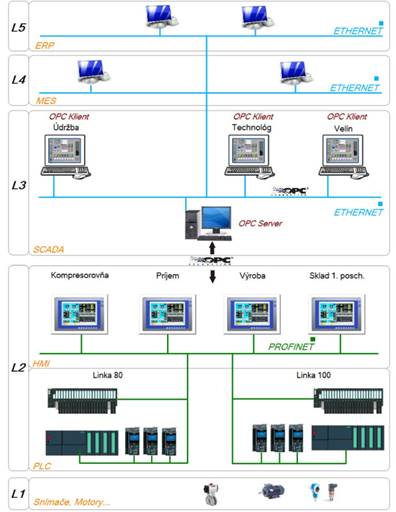

Siemens PLC infrastructure using PROFINET

for Production Logic Control

Redundant, failsafe and secured

SCADA for monitoring and control

SCADA system

(one supervisory system for all processes, process network, teleservice)

Data acquisition from stages and machines

Manufacturing execution system customized for margarine plant production (MES):

Traceability and consumption reports

Quality assurance

Production planning

Production execution

Effectivity: OEE

Packaging, WMS, expenditure

Cyber security, escalation and safety routines

references

Contact

DATANOVA, s. r. o.

Office Poprad:

Pavlovova 11

Poprad 058 01

SLOVAKIA

Ing. Daniel Pešek

Tel: +421 918 871 231

email: daniel.pesek@datanova.sk